Next generation of gasification system far below standard values of laws and regulations for dioxins and dust

Most of combustibles can be combusted easily and completely if they are combusted after gasification.

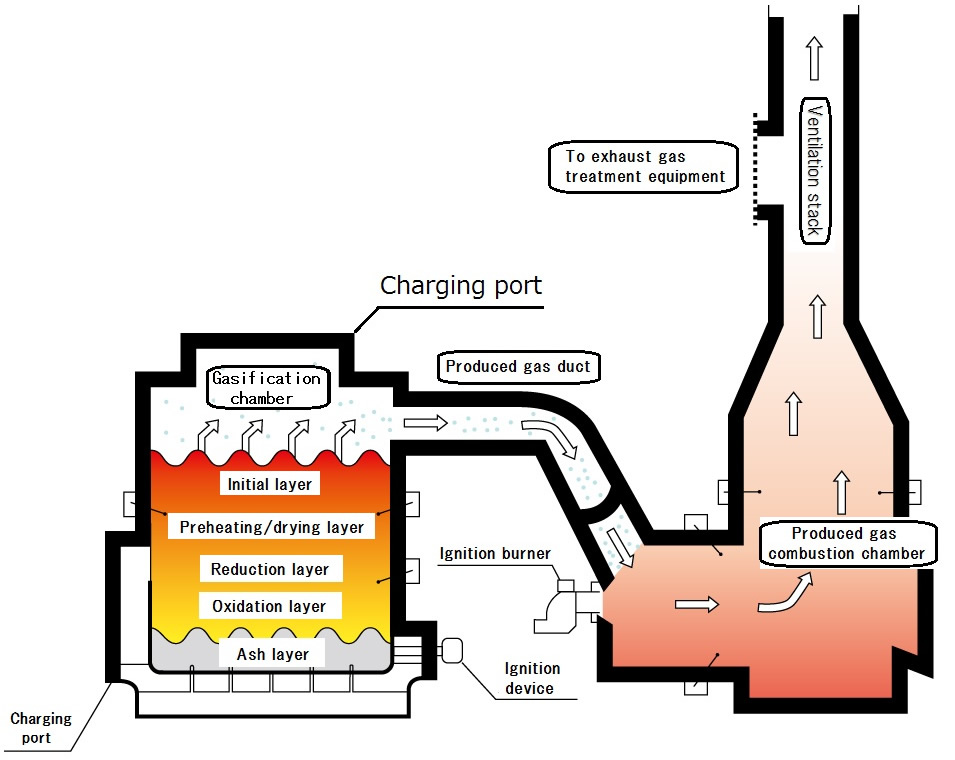

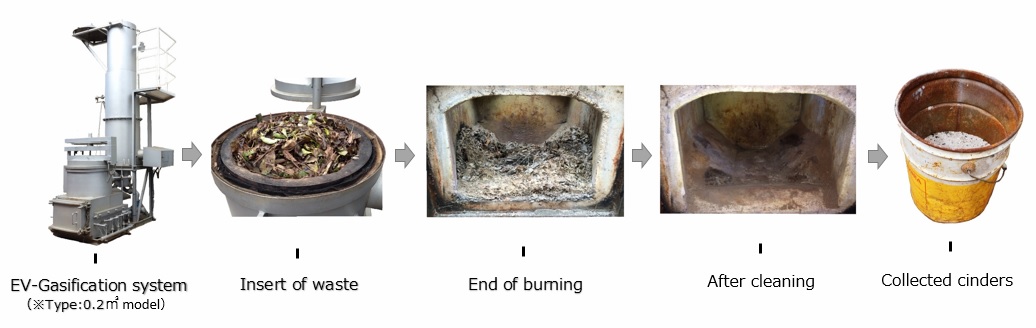

Being designed on the basis of this principle, EV-gasification system is a batch-type system which is equipped with the two chambers, such as the “gasification chamber” gasifying the combustible waste, and the “produced gas combustion chamber” combusting the gas produced in the gasification chamber. And, it can deal with unwanted substances and waste in an ideal manner without generating any smoke or smell.

About 3R

In our country, the solution measure was called for to break away from the economic society of the "mass production, mass consumption, and mass disposal" type and establish a "Recycling-based Society" with a low impact on the environment. As the law forming a fundamental framework for promoting a recycling-based society, "The Basic Act for Establishing Recycling Recycling-based Society" was enacted in 2000. what was held up herein is the way of thinking - "3R" oriented reducing waste.

Priorities stipulated in "The Basic Act for Establishing Recycling-based Society" are as follows

- To reduce as much generated waste as possible (reduce)

- To use repetitively what became unnecessary as much as possible (reuse)

- To recycle as resources what is unable to be used repetitively (recycle)

- To burn what is unable to be used as resources to utilize the heat (thermal recycle)

- To finally dispose properly, without polluting the environment, what items have no other choice

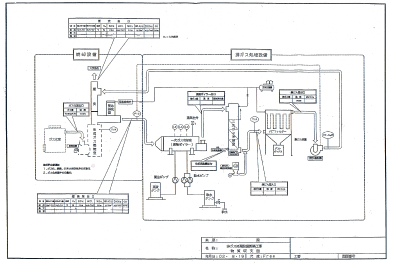

Outline of device

First, part of combustible waste charged in the “gasification chamber” is ignited, and other combustibles are dried and heat degraded by the combustion heat, and are converted into combustible gas. This gas is sent to the “produced gas combustion chamber,” where the gas is mixed with air, and all is combusted by igniting by the burner. Therefore, different from the former direct-combustion type gasifiers, no high-molecular materials (plastic, etc.) nor materials containing moisture are left unburnt.

■Main characteristics of the device

①Collective charging method (batch furnace)

②Heat degradation method

③Non-grate type

④All inner wall ceramic lining type

⑤Facilitated heat utilization

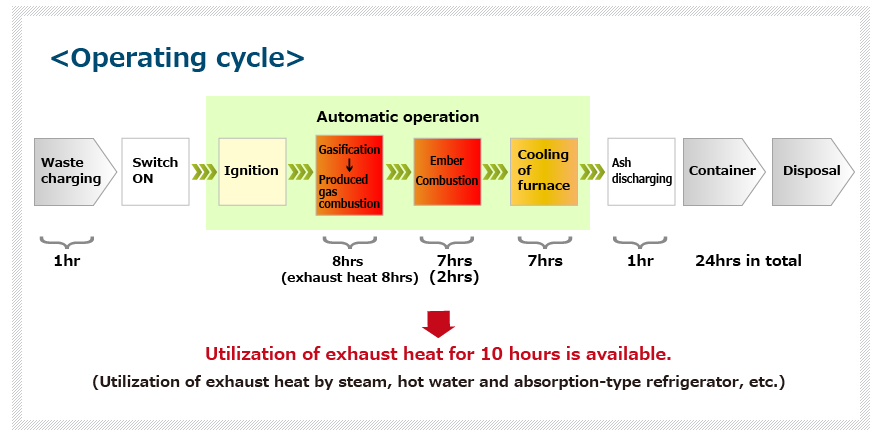

It makes 24-hour operation possible to utiliza plural units of gasification chambers.

Operation example

※ waste data: newspaper 6%, cardboard 4%, thinnings 5%, waste plastic 12%, waste rubber 8%, branch-leaf 65%.

Characteristics of device

Pollution-free

As the combustion in the “gasification chamber” is called “primary combustion” and that in the “produced gas combustion chamber” is called “secondary combustion,” waste is combusted elaborately two times in total, and therefore, it can be combusted cleanly like city gas or liquefied petroleum gas without generating any smell. Meanwhile, exhaust gas emission having a certain scale set forth in the laws and ordinances is equipped with exhaust gas disposal equipment, however, since exhaust gas in the gasification system is clean, the exhaust gas disposal equipment has a low load.

High economic efficiency

『The combustion in the “gasification chamber” promotes the gasification of this device, utilizing the combustion heat which was once ignited. Further, because the “produced gas combustion chamber” continues combustion only by produced gas after ignition, this device is useful in saving commercial fuel such as kerosene and heavy oil drastically.

Sufficient safety

The ejector installed in the “produced gas combustion chamber” is always sucking gas from the “gasification chamber” to keep a low pressure level, there’s no concern about backfire, etc.

Less cinders

As waste is combusted by embers after two times of combustion in the “gasification chamber” and the “produced gas combustion chamber,” only a slight amount of cinders are left finally. Residual ash can be removed easily by landfill disposal.

Power saving

Since this device adopts the batch method in which a certain amount of waste is combusted at a time, it is unnecessary to cast waste into the “gasification chamber” one after another. As all the combustion from start to end is carried out mechanically by the automatic control operation, almost no manual operation is required.

(For the relevant gasification system, the continuous quantitative charging equipment is exempted pursuant to the notification No.187 of the MHLW.)

Effective use of exhaust heat

This device is adapted to thermal recycling by the gasification of waste, which enables us various effective use of exhaust heat.

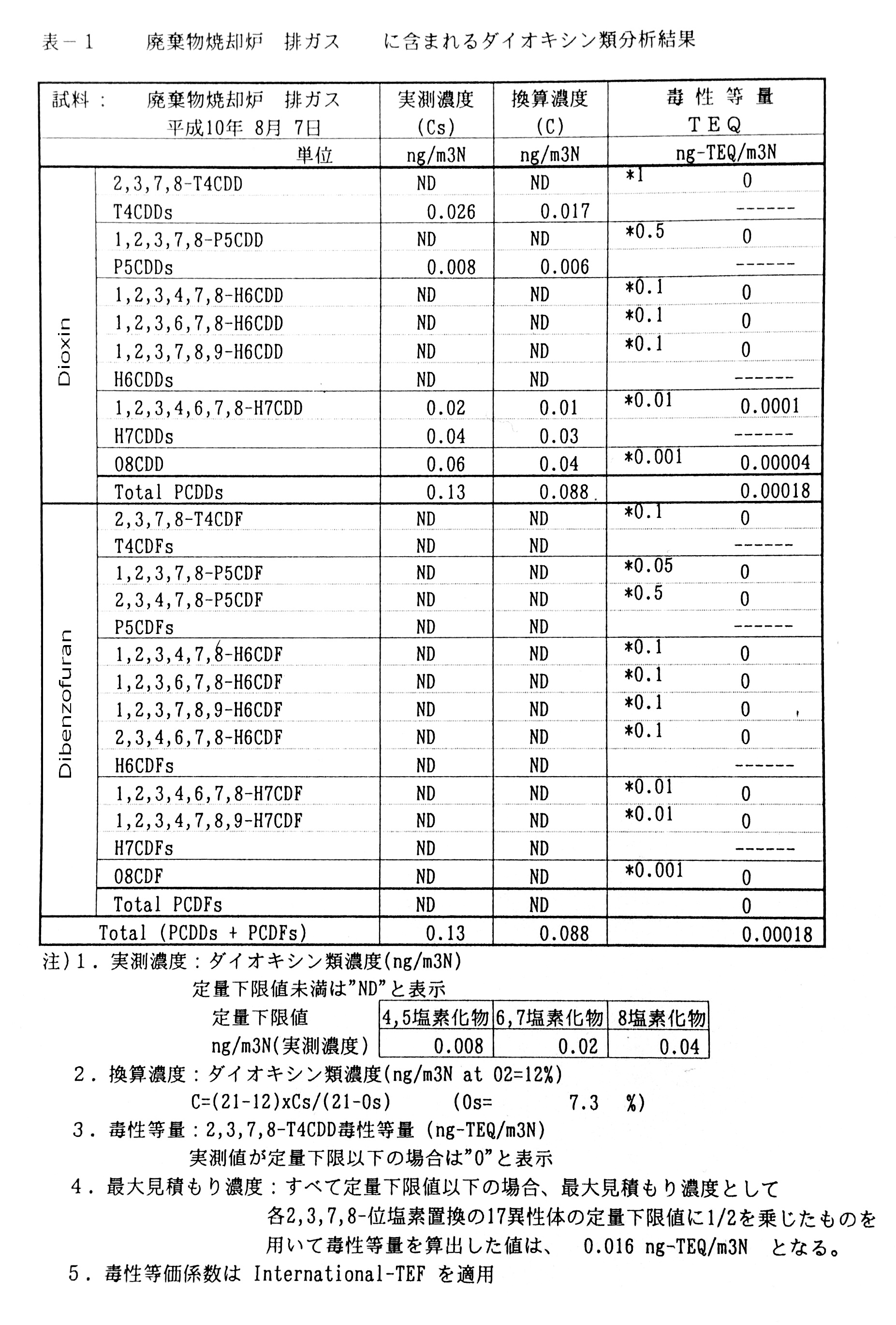

Dioxins measurement data

Effective use of exhaust heat

Example 1 Steam boiler

Gasification chamber ⇒ Produced gas combustion chamber ⇒ Smoke tube boiler combustion chamber

Example 2 Scrap car aluminum winnowing recovery

Gasification chamber ⇒ Produced gas combustion chamber ⇒ Melting furnace (reverberatory furnace)

Example 3 Poultry manure drying

Gasification chamber ⇒ Produced gas combustion chamber ⇒ (Hot gas) rotary kiln ⇒ Bromine-containing gas ⇒ Deodorizing furnace

Example 4 Melting of aluminum scrap (melting for casting)

Gasification chamber ⇒ Produced gas combustion chamber used also for melting furnace (reverberatory furnace)

Example 5 Heat degradation of process gas in manufacturing factory

Gasification chamber ⇒ Produced gas combustion chamber used also for heat degradation of bromine-containing gas (blowing into produced gas combustion chamber)

Example 6 Combustion and evaporation of sewage

Gasification chamber ⇒ Produced gas combustion chamber used also for combustion of sewage (dripping into produced gas combustion chamber)

Example 7 Combustion of waste paint (spraying)

Gasification chamber ⇒ Produced gas combustion chamber used also for combustion of waste paint (spraying on produced gas combustion chamber)

Example 8 Hot water boiler

Gasification chamber ⇒ Produced gas combustion chamber used also for combustion of waste paint (double boiler on the wall in produced gas combustion chamber side)

Processing object

| ○Plastic waste | : Packing material, material bag, vinyl bag, FRP, palette, etc. |

| ○Paper waste | : Packing material, corrugated cardboard, confidential documents, etc. |

| ○Wood waste | : Waste palette, thinning lumber, packaging material, construction waste, driftwoods piled in dam, etc. |

| ○Textile waste | : Jute bag, oil waste cloth, blanket, toweling blanket, etc. |

| ○Animal/plant residue | : Animal/plant waste, vegetable waste, expired foods, tea leaves, etc. |

| ○Rubber | : Surgical gloves, waste tire, etc. |

| ○Corpus | : Waste discharged from the livestock industry. |

| ○Sludge | : Food sludge cake, etc. |

| ○Medical waste | : Plastic medical apparatus, gauze, absorbent cotton, etc. |

| (Generally dangerous materials, such as airtight containers, explosives, solvent, radioactive contaminants, etc., and harmful materials such as mercury, cadmium, etc. are not subject to the gasification process.) | |

Especially, for medical waste, etc. which should be charged with being kept in a collection container and gasified in an airtight condition, this device works as the optimal system also in terms of safety and health.

Designing, installation

As the kind, size and amount, etc. of waste are different in each enterprise or factory, we each time calculate various data, such as size, capacity, etc. to design, manufacture and supply the most suitable EV-gasification system. Also, we will take charge of the notification at the installation and whole maintenance after the installation.